Swissloop Tunneling

A new way of building tunnels.

Engineering the future of underground mobility.

Are you passionate about bold engineering, hands-on experience, and working on projects that push boundaries? At Swissloop Tunneling, we build next-generation micro tunnel boring machines (MTBMs) and compete in Elon Musk’s Not-a-Boring Competition (NaBC) – and we want you to be part of the journey.

Founded in late 2020, we’ve grown into a team of over 100 active members and alumni, bringing together students from more than 12 countries and a wide range of engineering and business disciplines. Whether you’re into mechanical design, electronics, software, project management, finance, design or communications—there’s a place for you on the team.

Up until now, we’ve competed in three editions of the Not-a-Boring Competition, won once, placed second twice, and brought home three awards. But beyond the competition, we’re developing real-world tunneling technology that could transform how cities build infrastructure—faster, cleaner, and with minimal disruption.

Why Join?

-

Real Impact: Work on a project that bridges research and real-world application.

-

Cross-Disciplinary Teamwork: Collaborate with fellow students from mechanical engineering, robotics, computer science, physics, business, and more.

-

Network & Recognition: Present your work internationally and connect with industry leaders.

-

Learning by Doing: Gain experience in hardware development, software systems, marketing, sponsorships, and more.

Whether you want to code for control systems, design electro-mechanical components, plan logistics, or help manage external partnerships—Swissloop Tunneling is your launchpad.

Ready to dig deep? Join us and be part of building the tunnels of tomorrow.

Swissloop Tunneling’s Journey

8.10

0.606

3.1

200

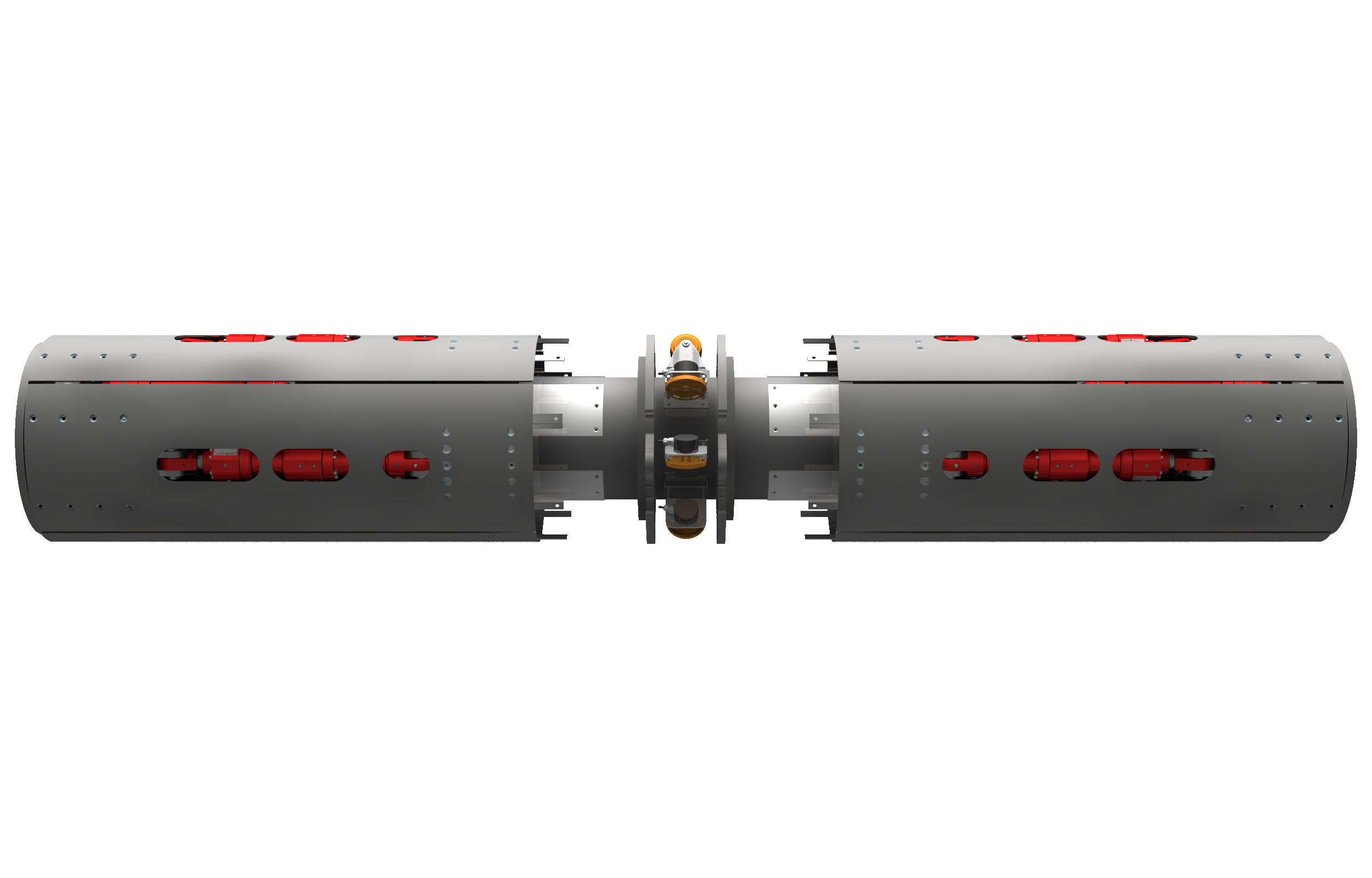

Meet Groundhog Gamma

Swissloop Tunneling's newest generation of machine with extensively reworked erosion, tunnel lining, and propulsion systems.

“Swissloop Tunneling is a great example of a student initiative that stands for technology, team spirit, and a bold vision. ETH Zurich considers itself fortunate to count such committed young personalities among its students.”

Prof. Dr. Joël MesotPresident of ETH Zurich

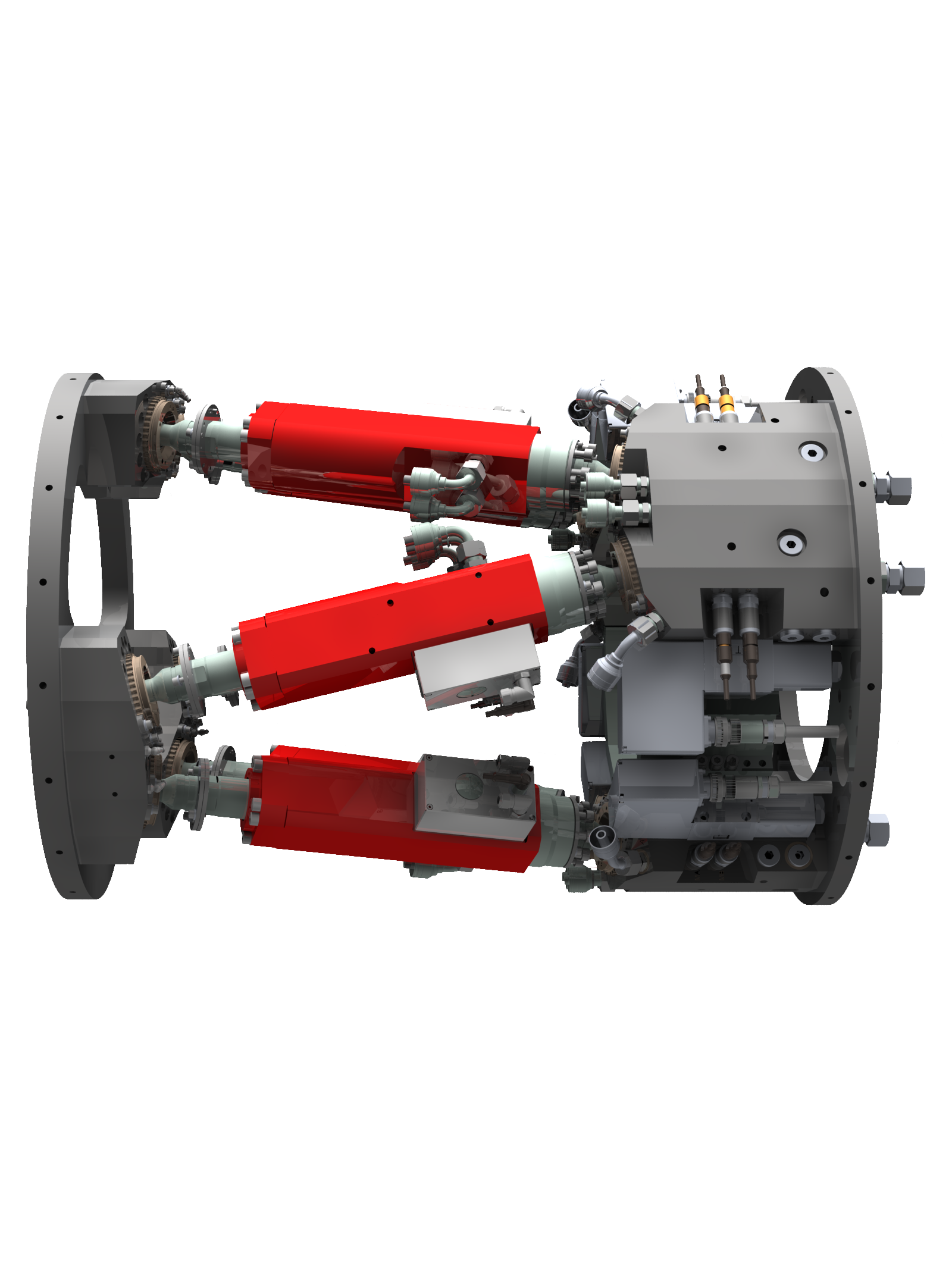

The all-new Erosion System is engineered to tackle the infamous sticky clay of Bastrop, Texas. Equipped with a cutting-edge ground conditioning mechanism, it pumps a specialized foam to the tunnel face—modifying the cohesive and adhesive properties of the soil. This not only helps tame high-plasticity clay but significantly boosts the efficiency of our suctioning system compared to our predecessor, Groundhog Alpha and Beta.

But clay isn’t the only challenge—the subsystem also crushes tougher rock formations with ease, thanks to a powerful torque of 9.5 kNm and a steady 12 rpm rotation. Larger rocks and pebbles are ground down and fed into the Venturi pump, the beating heart of our tunneling system. Whether clay or stone, the Erosion System makes way.

Meet our Tunnel Lining System – a continuous extrusion marvel that builds the tunnel as we dig it. A custom 15 mm thick pipe is formed in real time from a high-performance thermoplastic polymer, engineered to withstand intense thermal loads.

Inside the machine, a powerful extruder melts and molds the polymer into the perfect shape. At the same time, an integrated heating/cooling unit ensures ideal processing temperatures. Outside the tunnel, a pneumatic system blasts polymer granules into the machine at 70 km/h, whilst a water-cooling aggregate locks in the strength of the newly formed tunnel lining.

The result? A fully continuous, uninterrupted tunnel construction process – a major leap forward compared to conventional TBMs that must pause to install support structures like tubbing segments.

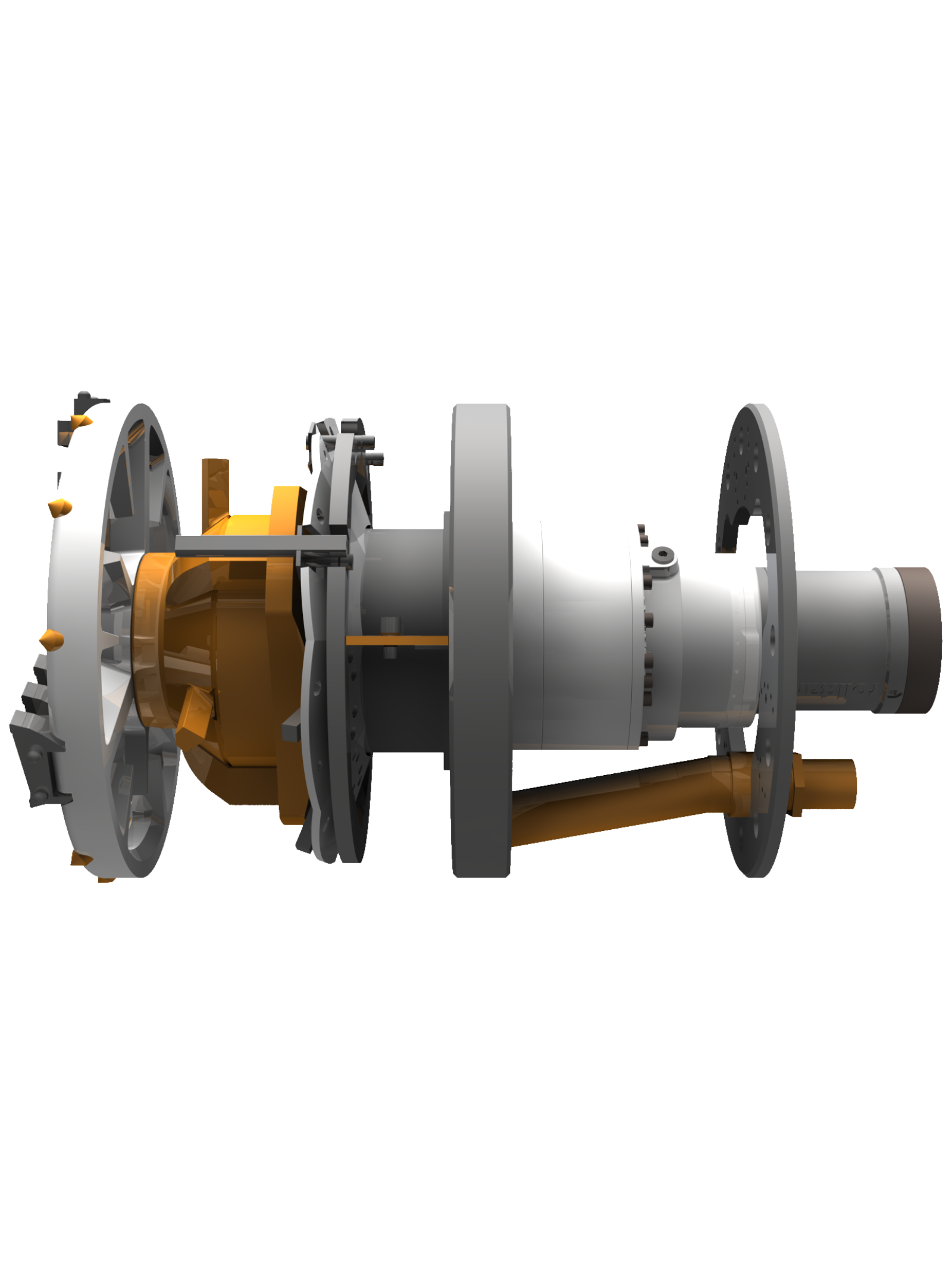

The Steering System is a two-in-one powerhouse of precision and adaptability. At its core is our custom-designed hydraulic hexapod, giving the machine full six degrees of freedom – allowing it to carve out perfectly curved tunnels with surgical accuracy.

But that’s not all. With a custom software twist, this same mechanism doubles as a jackhammer, capable of generating intense vibrations of up to 20 Hz, helping break through more resistant layers of ground.

Together with an integrated network of 85 sensors, this system enables near-autonomous navigation, guiding the machine with millimeter-level precision through even the trickiest terrain.

The Propulsion System powers the machine forward with coordinated force and finesse. Sixteen high-performance hydraulic cylinders, working in tandem with eight strategically placed gripper plates, press firmly against the tunnel wall to deliver 200 kN of controlled pushing force.

This “inchworm-like” movement ensures smooth, continuous progress through the underground—perfectly synchronized with the steering and excavation systems. It’s how we keep things moving without ever losing our grip.

Frequently asked questions

What is the purpose of our machine?

Our micro tunnel boring machine (MTBM) is designed for use in urban settings, for example to pursue utility projects with minimal impacts such as reduced road and open urban area closures.

What if I do not fulfull all the requirements that Swissloop Tunneling is looking for?

The requirements we add to the descriptions to open positions outline the optimal parameters we seek. However, everything can be learned or extended throughout your experience within the team. We encourage you to submit your application even if you don’t think you meet all the criteria. Your reliability, commitment, and passion for innovation are the most valuable traits we look for.

What is the expected weekly workload?

The weekly workload depends on the type and field of position, e.g., a leadership position in the engineering division is different than a graphical designer position in the business division. Generally speaking, Swissloop Tunneling offers positions with an expected weekly workload of between 4 and 12 hours, however, this can vary depending on the time in the season. During competitions, the workload is drastically different than during examination seasons at the universities.